| Benefits |

|---|

| | |

| New generation of human-machine communication |

| Interactive 3-D visualization |

| Intuitive machine operation via 15“ multi-touch display |

| Compact, modern GMP-compliant machine design for ultimate pharma safety |

| Doors made of safety glass with soft closing function: durable, antistatic, scratch-proof |

| Transparent control cabinet |

| Ergonomic down to the last detail for optimum operating comfort |

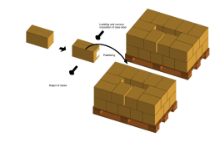

| Practical - pallet change without line downtime thanks to two pallet stations |

| Customized solution depending on installation situation |

| Intelligent safety technology |

| Pre-defined interfaces for integration of T&T system |

| Innovative labeling technology |

| Reliable KUKA robot technology in operation thousands of times around the world |

| New – fully integrated control cabinet for KUKA robot |

| Flexible palletizing schemes through multi pick & place system |

| Slip sheet magazine on request, for optimum product stability |

| Prepared for automatic format changeover |

| RFID format part detection on request |