| Benefits | |

|---|---|

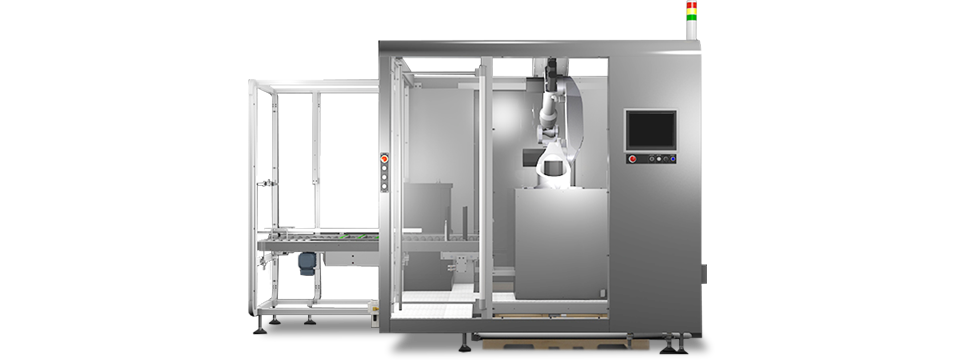

| Machine dimensions | 2300 x 2980 x 2250 mm [LxWxH] |

| Ceiling height | 2600 mm to allow for operating range of robot |

| Features | 2 pallet station |

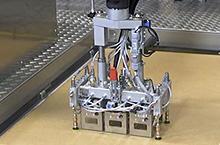

| Robot | KUKA KR 22 Cybertech |

| No. of robot axes | 6 |

| Min. format range | case 150 x 120 x 100 mm [L x W x H] |

| Max. format range | case 600 x 400 x 400 mm [L x W x H] |

| Performance | up to 10 palletizing cycles/min. |

| Control system | Schneider Electric PacDrive 3 / Rockwell Automation (Allen-Bradley) |

| Pallet size | 1200 x 800 mm - 1220 x 1016 mm (48" x 40") |

| Max. palletizing height | 1330 mm (including pallet) |

VERSIONS

HANDLING SYSTEMS

ACCESSORIES