| Benefits |

|---|

| | |

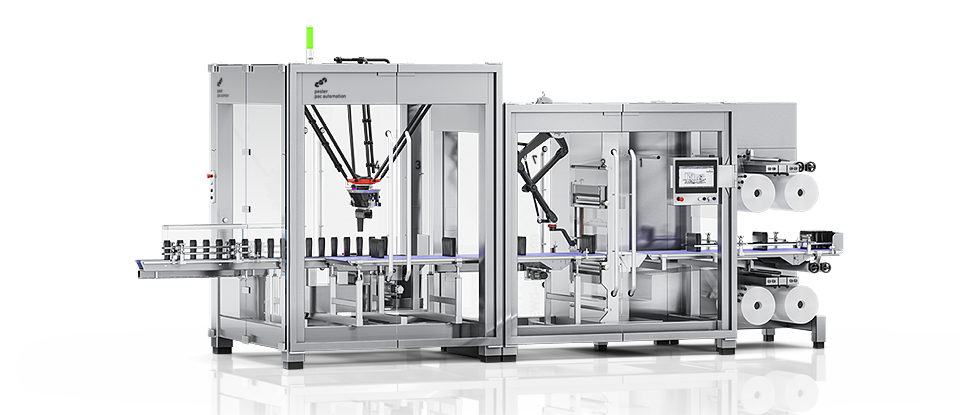

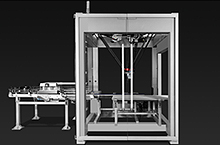

| World’s fastest stretchwrapper with new stretching technology |

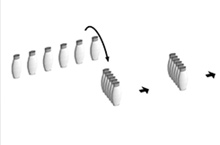

| Dual-lane operation for small bundles (e.g. packs of 3) |

| Robust, modular design for 24/7 operation |

| Fast assembly times with modular pre-assembled sealing unit |

| Fast and efficient collating via Delta robot (robotic pick & place unit), up to 180 bpm |

| Excellent handling of unconventionally shaped bottles |

| Multi format handling for small batches |

| Flexible and cost-effective - robotic pick & place handling without turning screws |

| Fast tool-less format changeover |

| Straightforward operation and maintenance - one single control system for robots and basic machine |

| New Allen Bradley HMI with tangius 4.0 multi touch display 16:9 |

| Transparent control cabinet |

| Machine guard with soft closure |

| Visual inspection of machine during ongoing production |

| Ergonomic film loading |