| Benefits | |

|---|---|

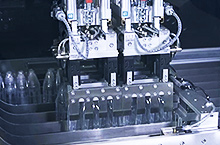

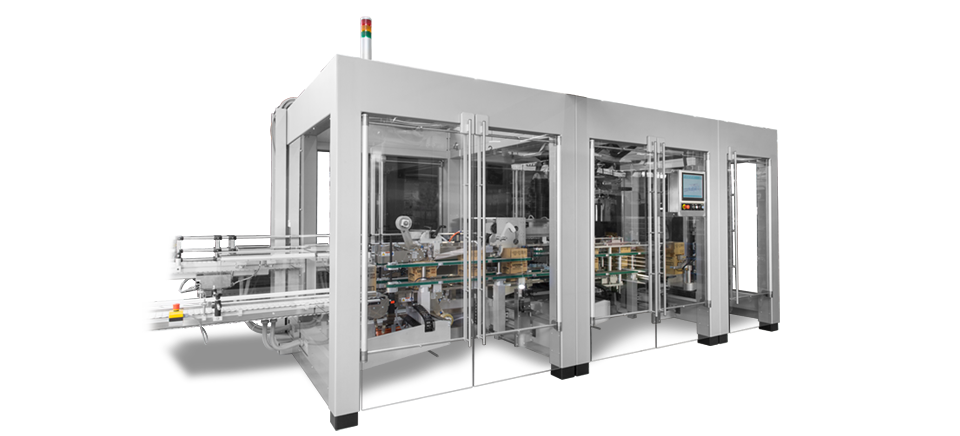

| Machine dimensions | 5120 x 2120 x 2350 mm [L x W x H] |

| Case type | American case |

| Sealing method | tape / hotmelt glue |

| Min. format range | tape 140 x 120 x 100 mm [L x W x H] hotmelt 140 x 85 x 100 mm [L x W x H] |

| Max. format range | tape 440 x 300 x 300 mm [L x W x H] hotmelt 400 x 300 x 300 mm [L x W x H] |

| Performance | up to 40 cases/min. |

| Control system | Schneider Electric PacDrive 3 / Rockwell Automation (Allen-Bradley) |

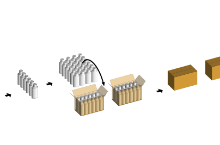

HANDLING SYSTEMS

ACCESSORIES