| Benefits | |

|---|---|

| Machine dimensions | 7600 x 2700 x 2600 mm [LxWxH] | ||||||||||||||||||||||||||||

| Ceiling height | 2850 mm to allow for operating range of robot | ||||||||||||||||||||||||||||

| Format Range |

| ||||||||||||||||||||||||||||

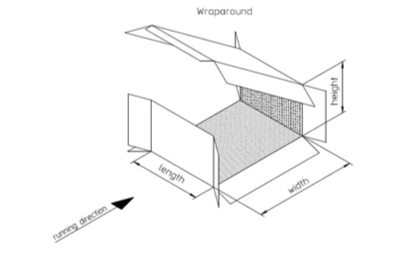

| Case type | Wraparound | ||||||||||||||||||||||||||||

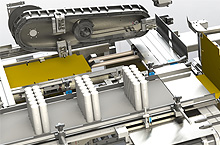

| Sealing method | hotmelt glue | ||||||||||||||||||||||||||||

| Changeover Time | Less than 10 Minutes | ||||||||||||||||||||||||||||

| Performance | up to 60 cases/min. | ||||||||||||||||||||||||||||

| Control system | Schneider Electric PacDrive 3 / Rockwell Automation (Allen-Bradley) | ||||||||||||||||||||||||||||

VERSIONS

HANDLING SYSTEMS

ACCESSORIES