| Benefits |

|---|

| | |

| New generation of human-machine communication |

| Interactive 3D visualization |

| Intuitive machine operation via 15" multi-touch display |

| Doors made of safety glass with soft closing function: durable, antistatic, scratch-proof |

| Transparent control cabinet |

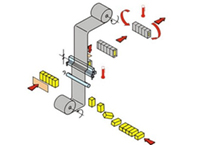

| Splicer - fully automatic film reel changeover without machine downtime |

| High-speed machine performance with low life-cycle costs |

| Compact, ergonomic, GMP-compatible machine design |

| Multifarious collation configurations for folding cartons |

| Quick and easy tool-less format changeover |

| Flexible collating possibilities |

| Ultimate pharma safety - controlled shrinking that is gentle on the product |