| Benefits |

|---|

| | |

| New generation of human-machine communication |

| Interactive 3D visualization |

| Intuitive machine operation via 15" multi-touch display |

| Doors made of safety glass with soft closing function: durable, antistatic, scratch-proof |

| Transparent control cabinet |

| Customized solution depending on installation situation |

| Modular architecture in pharma-compatible GMP design |

| Robotics: pester pac robot or KUKA KR 22 Cybertech |

| Pre-defined interfaces for integration of T&T system |

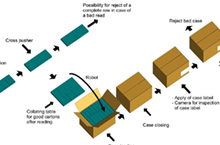

| Unique product protection – identification, labeling and monitoring at each level |

| Reliable case handling with innovative case extraction via cascade system |

| Ergonomic and fail-safe – new case magazine with zero access standard and user-friendly hand wheel adjustment |

| High-precision case handling by means of 4 servo-controlled toothed belts with lugs |

| RFID format part detection on request |

| Optimum accessibility for format changeover and cleaning from operating side |

| Simple, reproducible format changeover in less than 10 minutes |